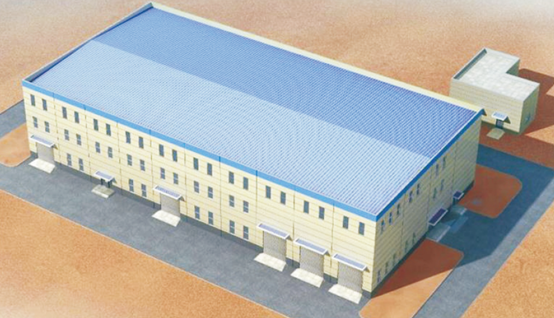

Multi Storey prefabricated Steel Structure Workshop factoryWith Warehouse Algeria Iraq Oman

- Steel Structure Warehouse

- Steel Structure Workshop

- Poultry Steel Structure

- Multi-storey Steel Structure

- School Steel Building

- Hospital Steel Structure

- Hotel Steel Building

- Stadium Steel Structure

- Airport Steel Structure

- Train Station Steel Structure

- Light Steel Villa

- Membrane Structure

- Steel Structure Buildings

Multi Storey prefabricated Steel Structure Workshop factoryWith Warehouse Algeria Iraq Oman

| Categories | Steel Structure Warehouse |

|---|---|

| Brand | ZYM steel structure building Manufacturer |

| Model | ZYM1 |

| Name | Algeria Iraq steel structure warehouse workshop |

| Key word | Algeria Iraq steel structure workshop with office |

| Design | 3D max,CAD for steel structure frame |

| Material | Q235,Q345B,SS400 steel structure |

| Foof | Galvanized color sheet or sandwich panel |

| Wall | Galvanized sheet for steel structure workshop |

| Place of project | Algeria steel structure workshop and warehouse |

| Delivery time | 30 days after steel structure drawing confirmation |

| Package | Steel structure frame pallet for 40HQ container |

| Application | workshop,warehouse,office,commercial bulding,shop |

| FOB port | Qingdao Guangdong Shanghai |

| Terms of Payment | L/C, D/A, Western Union, T/T |

| Update Time | Apr 16,2025 |

How to build a Steel Structure Building Project of Algeria Overhaul Plant

Project Name: Steel Structure Building Project of Algeria Overhaul Plant

Project Background: This is a collaborative project between China Electronics Import and Export Corporation and the local government of Algeria in 2017

Project details description: This project is the first large-scale communication vehicle maintenance plant in Algeria, with a construction area of approximately 10000 square meters, including a main plant, substation, and fire pump room. The main plant is a three story steel frame structure. This project is a foreign construction general contracting project, which started construction in March 2017 and was delivered for use in October 2018 after ribbon cutting inspection. It has been running well during use and is currently undergoing normal maintenance work.

Solution: At present, the main work is the maintenance treatment under the normalization of the COVID-19. Since the beginning of the epidemic, materials can now arrive at the project site normally, resident personnel have been vaccinated, and the epidemic prevention and control has been handled in accordance with effective plans and preplans, with personnel replacement once a year. At present, the risk is controllable.

Project Value: This project is another construction general contracting project of the company abroad, which has accumulated more experience for the company to execute general contracting projects abroad, especially in the construction organization and management of steel structure factories abroad. It only took three months from the entry of steel structures to the completion of the main structure, without any rework or safety or quality problems, once again proving what China's speed is.

How to finish the whole project following the steps:

Ⅰ-Communication And Design

Specificaitons as follows:

a) Provide all the structural steel required for the building which includes foundation anchor bolts, columns, Beams, Roof Beams, Roofing sheets, bolts…etc. (All the steel structure should be epoxy painted).

b) Provide all the Cladding material for the building wall including all required framing for fixing of cladding.

c) Provide all steel structure mezzanine decking materials.

d) Provide all staircases mentioned in the drawing. Tread: 280mm, Height: 167mm.

e) Provide hand railings (staircase) and railings (decks) as per shown in the drawings.|

f) Provide steel structure building Roofing Sheets including purling, heat insulation material and all required material for fixing of Roof.

g) Careful procedures for steel structure frame erection drawings giving importance to the given drawings.

h) Provide all railings including staircase railings in Stainless steel

i) Provide structural steel parts drawings and structural calculations ) steel Foundation and any other required civil work related designs should be provided.

k) Foundation of the steel structure building should be constrained within the build area and should not extend outside.

l) The steel structure warehouse Load bearing capacity of the soil should be 150 kn/m2.

m) Foundation depth should be 2 meter

The steel structure workshop layout and elevation are designed as follows:

Ⅱ- Confirmation drawings -Production-QC

Ⅲ Erection

1.5 DEFECT & PROTECTION DURING DELIVERY

During Delivery all delicate workshop materials shall be carefully handled and stored under cover in a manner to prevent deformation and damage to the materials and to prevent rusting and the accumulation of mud, dirt or other foreign matter on the metal work.

Tag:steel workshop, steel structure buildings

For further information feel free to contact us.

E-mail: sales@zyminfra.com

- Steel Structure Warehouse

- Steel Structure Workshop

- Poultry Steel Structure

- Multi-storey Steel Structure

- School Steel Building

- Hospital Steel Structure

- Hotel Steel Building

- Stadium Steel Structure

- Airport Steel Structure

- Train Station Steel Structure

- Light Steel Villa

- Membrane Structure

- Steel Structure Buildings