- Steel Structure Warehouse

- Steel Structure Workshop

- Poultry Steel Structure

- Multi-storey Steel Structure

- School Steel Building

- Hospital Steel Structure

- Hotel Steel Building

- Stadium Steel Structure

- Airport Steel Structure

- Train Station Steel Structure

- Light Steel Villa

- Membrane Structure

- Steel Structure Buildings

sandwich panels workshop

| Categories | Steel Structure Buildings |

|---|---|

| Brand | ZYM steel structure building Manufacturer |

| Model | ZYM1 |

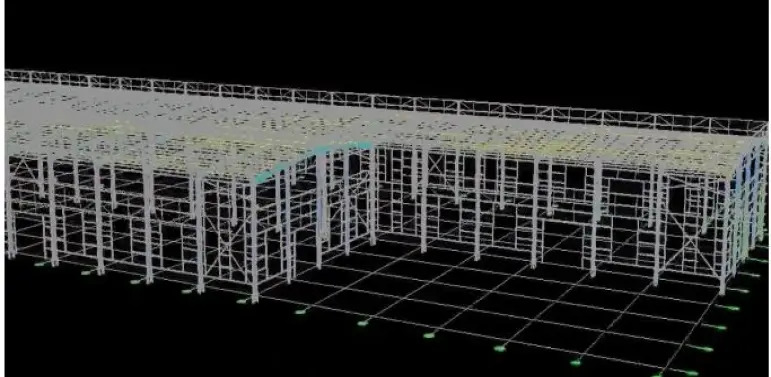

| Name | Indonesia steel structure warehouse workshop |

| Key word | Indonesia steel structure workshop with office |

| Design | 3D max,CAD for steel structure frame |

| Material | Q235,Q345B,SS400 steel structure |

| Foof | Galvanized color sheet or sandwich panel |

| Wall | Galvanized sheet for steel structure workshop |

| Place of project | Indonesia steel structure workshop and warehouse |

| Delivery time | 30 days after steel structure drawing confirmation |

| Package | Steel structure frame pallet for 40HQ container |

| Application | workshop,warehouse,office,commercial bulding,shop |

| FOB port | Qingdao Guangdong Shanghai |

| Terms of Payment | L/C, D/A, Western Union, T/T |

| Update Time | Apr 20,2025 |

ZhengYuanming Construction Engineering Co., Ltd.. is a manufacturer of steel structure building, steel structure materials, we had built many large commercial buildings,steel frame structure building,multi story steel structure warehouse,steel structure commercial building,galvanized steel structure building and many other steel structures.We have worldwide clients such as Paraguay, Chile, Colombia, Mexico, Australia, New Zealand, Isle of Man, etc.ZYM Team Group has a strong focus on manufacturing all major components of steel structure building ,we have 5 steel structure production lines. ZYM covers an area of more than 50,000 square meters, with excellent equipment, numerical control technology and high degree of automation. Our products are approved by PHI,TUV,BV,CE etc.

| Product name |

sandwich panels workshop |

|---|---|

| Brand Name |

ZYM |

| Model Number |

STEEL - 01 |

| Material |

Low alloy steel plate,nut etc |

| Brand |

ZYM sandwich panels workshop Manufacturer |

| Tolerance |

±1% |

| Keyword |

Prefab Portal Steel Structure Warehouse,warehouse prices,large scale workshop,steel brick workshop,prefab high-strength steel structure warehouse |

| Material |

Q235,Q345B,SS400 steel structure |

| Delivery time |

30 days after steel structure drawing confirmation |

| Certificate |

PHI,TUV,BV,CE etc. |

| Package |

Steel structure frame pallet for 40HQ container |

| Application |

steel frame structure building,multi story steel structure warehouse,steel structure commercial building,galvanized steel structure building |

| Processing Service |

Bending, Welding, Decoiling, Cutting, Punching |

| FOB port |

Qingdao Guangdong Shanghai |

| Terms of Payment |

L/C, D/A, Western Union, T/T |

| FOB port |

Qingdao Guangdong Shanghai |

| Processing Service |

Bending, Welding, Cutting, Punching, Pre-assembling, Painting |

| Project Solution Capability |

graphic design, 3D model design, total solution for projects |

| Main Materials |

light steel construction |

| Color |

Request, colorful |

| Design Style |

Modern |

| Characteristics |

Safe foundation, anti-seismic and windproof |

| Sales country |

Yemen,Puerto Rico,Grenada,Bahrain |

ZYM One-Stop Steel Structure Material

Dead load is 0.3 kN Live load is 0.5 kN Wind load is 0.4 kN

ZYM provide the integrated solutions for our clients . After the steel structure design , we arrange the steel steel structure building construction,two storey steel structure warehouse,astm steel structure warehouse,preficated steel structure warehouse,Big factory Steel Structure Warehouse,steel structure workshop design dwg,prefabricated building,workshop light steel structure . In the process , we provide the best quality steel structure and the quality is approved sandwich panels workshop services FAQs GuideAre you looking for a quick review guide about sandwich panels workshopservices?An ultimate FAQ buying guide is available to help you.This guide contains all the information about all the important facts, figures, and various processes regarding sandwich panels workshop services.Let’s continue!

2.How do the construction time and labor costs for sandwich panels workshop compare to traditional building methods?

3.What certifications do your products have?

4.Are sandwich panels workshop resistant to pests and termites?

5.What type of foundation is required for a steel structure building?

6.What are the most common applications for sandwich panels workshop?

7.What is the typical cost of maintenance for a steel structure building?

8.What are the design considerations for a sandwich panels workshop?

9.Can sandwich panels workshop be customized to fit specific design requirements?

10.What is the insulation and energy efficiency of sandwich panels workshop?

11.How does the structural integrity of a sandwich panels workshop improve safety?

12.What design options are available for the exterior aesthetics of a sandwich panels workshop?

1.Can sandwich panels workshop be expanded or modified in the future?

We operate our sandwich panels workshop business with integrity and honesty. Yes, steel structure buildings can be expanded or modified in the future. Steel is a very strong and durable material, so it can easily be modified to accommodate changes in the building's design or purpose. Steel structures can be expanded by adding additional steel components or by welding new steel components to existing ones. Steel structures can also be modified by cutting, welding, and bolting new components into place.

2.How do the construction time and labor costs for sandwich panels workshop compare to traditional building methods?

Our sandwich panels workshop products undergo strict quality control to ensure customer satisfaction. Steel structure buildings typically require less time and labor costs than traditional building methods. Steel structures are typically pre-engineered and pre-fabricated, meaning that much of the work is done off-site in a factory setting. This reduces the amount of time and labor needed on-site, as well as the amount of waste generated. Additionally, steel structures are often easier to assemble than traditional building methods, which can further reduce labor costs.

3.What certifications do your products have?

Providing safety and quality steel structure systems, ZYM Team Group has a strong focus on manufacturing all major components of steel structure building ,we have 5 steel structure production lines. ZYM covers an area of more than 50,000 square meters, with excellent equipment, numerical control technology and high degree of automation. Our products are approved by PHI,TUV,BV,CE etc.

4.Are sandwich panels workshop resistant to pests and termites?

Our products & services cover a wide range of areas and meet the needs of different fields. Yes, steel structure buildings are resistant to pests and termites. Steel is a non-porous material, which means that pests and termites cannot penetrate it. Steel is also highly durable and can withstand extreme weather conditions, making it an ideal material for buildings.

5.What type of foundation is required for a steel structure building?

We are a professional sandwich panels workshop company dedicated to providing high quality products and services. The foundation type required for a steel structure building will depend on the size and type of building, as well as the soil conditions of the site. Generally, steel structure buildings require a concrete slab-on-grade foundation, a shallow foundation, or a deep foundation.

6.What are the most common applications for sandwich panels workshop?

We have a good reputation and image in the industry. The quality and price advantage of sandwich panels workshop products is an important factor in our hard overseas market. 1. Warehouses 2. Industrial Buildings 3. Agricultural Buildings 4. Retail Stores 5. Offices 6. Aircraft Hangars 7. Churches 8. Garages 9. Sports Facilities 10. Carports

7.What is the typical cost of maintenance for a steel structure building?

We pay attention to the transformation of intellectual property protection and innovation achievements. Your OEM or ODM order design we have a complete confidentiality system. The cost of maintenance for a steel structure building can vary greatly depending on the size and complexity of the building. Generally, the cost of maintenance for a steel structure building is between 1-2% of the total cost of the building. This cost includes regular inspections, painting, and repairs.

8.What are the design considerations for a sandwich panels workshop?

We have a wide range of sandwich panels workshop customer groups and establishes long -term cooperative relationships with partners. The countries we provide services include Bermuda. 1. Structural Design: The structural design of a steel structure building should consider the building’s load-bearing capacity, the type of steel used, the size and shape of the steel members, and the connections between the members. 2. Architectural Design: The architectural design of a steel structure building should consider the building’s aesthetic appeal, the type of cladding used, the size and shape of the building, and the overall layout of the building. 3. Fire Protection: The fire protection of a steel structure building should consider the type of fire protection system used, the type of steel used, and the fire resistance rating of the steel. 4. Environmental Considerations: The environmental considerations of a steel structure building should consider the type of steel used, the type of insulation used, and the energy efficiency of the building. 5. Maintenance: The maintenance of a steel structure building should consider the type of steel used, the type of coating used, and the maintenance schedule for the building.

9.Can sandwich panels workshop be customized to fit specific design requirements?

We have rich industry experience and professional knowledge, and have strong competitiveness in the market. Yes, steel structure buildings can be customized to fit specific design requirements. Steel structure buildings are highly customizable and can be designed to meet the exact needs of the customer. Steel structure buildings can be designed to fit any size, shape, or style, and can be customized with a variety of features such as windows, doors, insulation, and more.

10.What is the insulation and energy efficiency of sandwich panels workshop?

We actively participate in the sandwich panels workshop industry associations and organization activities. The corporate social responsibility performed well, and the focus of brand building and promotion Steel structure buildings are highly energy efficient and can be insulated to meet the highest energy efficiency standards. Steel is a great conductor of heat, so it is important to use insulation to reduce heat transfer. Steel structure buildings can be insulated with a variety of materials, including fiberglass, cellulose, and spray foam. Steel structure buildings can also be designed to meet the highest energy efficiency standards, such as LEED certification.

11.How does the structural integrity of a sandwich panels workshop improve safety?

We are a new sandwich panels workshop manufacturer. The structural integrity of a steel structure building improves safety by providing a strong and stable framework that can withstand the forces of nature, such as wind, snow, and earthquakes. Steel is a strong and durable material that is resistant to corrosion and can be designed to meet specific structural requirements. Steel structures are also fire-resistant, which helps to protect occupants in the event of a fire. Additionally, steel structures are often designed with redundancy, meaning that if one part of the structure fails, the other parts can still support the building. This helps to ensure that the building remains standing and safe for occupants.

12.What design options are available for the exterior aesthetics of a sandwich panels workshop?

We should have a stable supply chain and logistics capabilities, and provide customers with high -quality, low -priced sandwich panels workshop products. 1. Paint: Steel structures can be painted in a variety of colors to match the surrounding environment. 2. Siding: Steel structures can be clad in a variety of siding materials such as brick, stone, stucco, wood, or metal. 3. Windows and Doors: Steel structures can be fitted with a variety of windows and doors to match the desired aesthetic. 4. Roofing: Steel structures can be fitted with a variety of roofing materials such as metal, shingles, or tiles. 5. Lighting: Steel structures can be fitted with a variety of lighting fixtures to enhance the exterior aesthetic. 6. Awnings: Steel structures can be fitted with awnings to provide shade and protection from the elements.

- Steel Structure Warehouse

- Steel Structure Workshop

- Poultry Steel Structure

- Multi-storey Steel Structure

- School Steel Building

- Hospital Steel Structure

- Hotel Steel Building

- Stadium Steel Structure

- Airport Steel Structure

- Train Station Steel Structure

- Light Steel Villa

- Membrane Structure

- Steel Structure Buildings