- Steel Structure Warehouse

- Steel Structure Workshop

- Poultry Steel Structure

- Multi-storey Steel Structure

- School Steel Building

- Hospital Steel Structure

- Hotel Steel Building

- Stadium Steel Structure

- Airport Steel Structure

- Train Station Steel Structure

- Light Steel Villa

- Membrane Structure

- Steel Structure Buildings

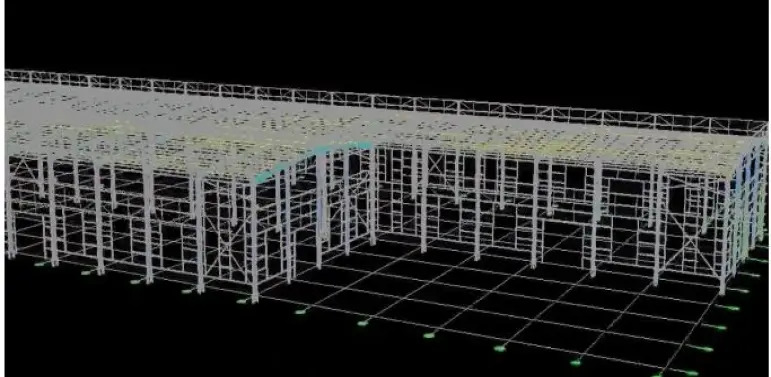

fabrication workshop

| Categories | Steel Structure Buildings |

|---|---|

| Brand | ZYM steel structure building Manufacturer |

| Model | ZYM1 |

| Name | Indonesia steel structure warehouse workshop |

| Key word | Indonesia steel structure workshop with office |

| Design | 3D max,CAD for steel structure frame |

| Material | Q235,Q345B,SS400 steel structure |

| Foof | Galvanized color sheet or sandwich panel |

| Wall | Galvanized sheet for steel structure workshop |

| Place of project | Indonesia steel structure workshop and warehouse |

| Delivery time | 30 days after steel structure drawing confirmation |

| Package | Steel structure frame pallet for 40HQ container |

| Application | workshop,warehouse,office,commercial bulding,shop |

| FOB port | Qingdao Guangdong Shanghai |

| Terms of Payment | L/C, D/A, Western Union, T/T |

| Update Time | Apr 20,2025 |

ZhengYuanming Construction Engineering Co., Ltd.. is a comprehensive building material manufacturer and provider focusing on steel structure construction. such as sandwich panel steel structur warehous workshops,High quality steel structure warehouse ,small steel structure warehouse,steel structure buildings,steel structure workshop prefabricated building,metal pre-engineered prefab workshop,industry construction steel structure workshop,structure steel workshop for production,prefab warehouse,Steel Structure Workshop in China etc .Since its establishment, the company has served more than 60 countries and regions in the world. Antigua and Barbuda, and Africa have our partners. Through high-quality products and sincere service, we are well received by customers. We also welcome and look forward to in-depth cooperation with more partners in the world in the future.ZYM has three modern base centers, one center is responsible for design and R&D, one center handles production ,one center is for the sales and service.The group maintains production facilities for high-quality prefabricated steel,steel structure with an annual output of 50,000-60,000 tons of steel structure.

| Product name |

fabrication workshop |

|---|---|

| Brand Name |

ZYM |

| Model Number |

STEEL - 01 |

| Material |

Welded steel pipe,and stainless steel etc |

| Brand |

ZYM fabrication workshop Manufacturer |

| Tolerance |

±1% |

| Keyword |

Industrial Shed Design Steel Structure Warehouses,prefab workshop building,building a steel structure,prefabricated big steel structure warehouse |

| Material |

Q235,Q345B,SS400 steel structure |

| Delivery time |

30 days after steel structure drawing confirmation |

| Certificate |

PHI,TUV,BV,CE etc. |

| Package |

Steel structure frame pallet for 40HQ container |

| Application |

Single steel structure warehouse,steel parking structure,galvanized steel structure warehouse,engineering steel structure warehouse |

| Processing Service |

Bending, Welding, Decoiling, Cutting, Punching |

| FOB port |

Qingdao Guangdong Shanghai |

| Terms of Payment |

L/C, D/A, Western Union, T/T |

| FOB port |

Qingdao Guangdong Shanghai |

| Processing Service |

Bending, Welding, Cutting, Punching, Pre-assembling, Painting |

| Project Solution Capability |

graphic design, 3D model design, total solution for projects |

| Main Materials |

light steel construction |

| Color |

Request, colorful |

| Design Style |

Modern |

| Characteristics |

Safe foundation, anti-seismic and windproof |

| Sales country |

Ireland,Wallis and Futuna,Gabon,Wake Island |

Prefabricated workshop

ZYM One-Stop Steel Structure Material

Project Name: fabrication workshopRecently, multiple steel structure projects undertaken by our company are steadily advancing and continuously making new progress.The company's project department and steel structure processing plant seize the golden period of construction and ensure the perfect performance of the project.fabrication workshop services FAQs GuideAre you looking for a quick review guide about fabrication workshopservices?An ultimate FAQ buying guide is available to help you.This guide contains all the information about all the important facts, figures, and various processes regarding fabrication workshop services.Let’s continue!

2.What is the maximum height that can be achieved with a ?

3.What are the design considerations for a fabrication workshop?

4.What are the fire safety standards for fabrication workshop?

5.Do you offer service for installation?

6.How does the construction time of a steel structure building compare to traditional methods?

7.What certifications do your products have?

8.How do the construction time and labor costs for fabrication workshop compare to traditional building methods?

9.What kind of company you are?

10.What is Steel Structure and How Does it Differ from Traditional Construction?

11.fabrication workshop What factors contribute to the strength and stability of a steel structure building?

1.How does the weight of a steel structure building affect site preparation and construction?

We pay attention to employee development and benefits, and provide a good working environment in order to improve the efficiency of employees and improve the quality management of fabrication workshop products. The weight of a steel structure building affects site preparation and construction in several ways. First, the weight of the steel structure must be taken into account when designing the foundation and other structural elements. The foundation must be designed to support the weight of the steel structure, and the soil must be able to bear the load. Additionally, the weight of the steel structure must be taken into account when designing the crane and other lifting equipment used to move the steel structure into place. Finally, the weight of the steel structure must be taken into account when designing the temporary bracing and other support systems used during construction.

2.What is the maximum height that can be achieved with a ?

We focus on providing high fabrication workshop quality products and services. The maximum height of a steel structure building is determined by the strength of the steel used, the design of the building, and local building codes. Generally, steel structures can reach heights of up to 30 stories or more.

3.What are the design considerations for a fabrication workshop?

We have a wide range of fabrication workshop customer groups and establishes long -term cooperative relationships with partners. The countries we provide services include Tokelau. 1. Structural Design: The structural design of a steel structure building should consider the building’s load-bearing capacity, the type of steel used, the size and shape of the steel members, and the connections between the members. 2. Architectural Design: The architectural design of a steel structure building should consider the building’s aesthetic appeal, the type of cladding used, the size and shape of the building, and the overall layout of the building. 3. Fire Protection: The fire protection of a steel structure building should consider the type of fire protection system used, the type of steel used, and the fire resistance rating of the steel. 4. Environmental Considerations: The environmental considerations of a steel structure building should consider the type of steel used, the type of insulation used, and the energy efficiency of the building. 5. Maintenance: The maintenance of a steel structure building should consider the type of steel used, the type of coating used, and the maintenance schedule for the building.

4.What are the fire safety standards for fabrication workshop?

Our fabrication workshop products have competitive and differentiated advantages, and actively promote digital transformation and innovation. 1. Steel structures must be designed and constructed in accordance with the applicable building codes and standards. 2. Fire-resistant materials must be used in the construction of steel structures. 3. Fire-resistant coatings must be applied to steel structures to protect them from fire. 4. Fire-resistant insulation must be installed in steel structures to reduce the spread of fire. 5. Fire-resistant doors and windows must be installed in steel structures to prevent the spread of fire. 6. Fire-resistant sprinkler systems must be installed in steel structures to control the spread of fire. 7. Fire-resistant smoke detectors must be installed in steel structures to detect the presence of smoke. 8. Fire-resistant fire extinguishers must be installed in steel structures to extinguish fires.

5.Do you offer service for installation?

We will furnish you the detailed construction drawing and the construction manual which could help you to erect and install the building step by step. We also could send the engineer to your local to help you if neede.

6.How does the construction time of a steel structure building compare to traditional methods?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. Steel structure buildings typically take less time to construct than traditional methods. Steel structures can be erected in a fraction of the time it takes to build a traditional building, often in as little as half the time. Steel structures are also more cost-effective, as they require fewer materials and labor to construct. Additionally, steel structures are more durable and require less maintenance over time.

7.What certifications do your products have?

Providing safety and quality steel structure systems, ZYM Team Group has a strong focus on manufacturing all major components of steel structure building ,we have 5 steel structure production lines. ZYM covers an area of more than 50,000 square meters, with excellent equipment, numerical control technology and high degree of automation. Our products are approved by PHI,TUV,BV,CE etc.

8.How do the construction time and labor costs for fabrication workshop compare to traditional building methods?

Our fabrication workshop products undergo strict quality control to ensure customer satisfaction. Steel structure buildings typically require less time and labor costs than traditional building methods. Steel structures are typically pre-engineered and pre-fabricated, meaning that much of the work is done off-site in a factory setting. This reduces the amount of time and labor needed on-site, as well as the amount of waste generated. Additionally, steel structures are often easier to assemble than traditional building methods, which can further reduce labor costs.

9.What kind of company you are?

ZYM Team Group focus on creating and protecting value. We offer the full range of steel structure products, from steel material to highly engineered building systems, as well as accessories. Our full production line offers high-quality products at competitive prices. We pay attention to every little detail to ensure our steel structure more perfect. ZYM has three modern base centers, one center is responsible for design and R&D, one center handles production ,one center is for the sales and service.The group maintains production facilities for high-quality prefabricated steel,steel structure with an annual output of 50,000-60,000 tons of steel structure.

10.What is Steel Structure and How Does it Differ from Traditional Construction?

We should perform well in market competition, and the prices of fabrication workshop products have a great competitive advantage. Steel structure is a type of construction that uses steel as the primary structural element. It is typically used for large buildings and bridges, and is becoming increasingly popular for residential and commercial construction. Steel structure differs from traditional construction in that it uses steel components instead of wood, concrete, or other materials. Steel structure is lighter, stronger, and more durable than traditional construction, and is also more cost-effective. Steel structure also requires less maintenance and is more resistant to fire, wind, and other natural disasters.

11.fabrication workshop What factors contribute to the strength and stability of a steel structure building?

We have broad development space in domestic and foreign markets. fabrication workshop have great advantages in terms of price, quality, and delivery date. 1. Design: The design of a steel structure building is critical to its strength and stability. The design should take into account the loads that the building will be subjected to, such as wind, snow, and seismic forces. 2. Connections: The connections between the steel members are also important for the strength and stability of the building. The connections should be designed to be strong and secure, and should be able to resist the forces that the building will be subjected to. 3. Materials: The materials used in the construction of the steel structure building should be of high quality and should be able to withstand the loads that the building will be subjected to. 4. Foundation: The foundation of the building should be designed to be strong and stable, and should be able to support the weight of the building. 5. Maintenance: Regular maintenance of the steel structure building is important to ensure its strength and stability. This includes inspecting the building for any signs of corrosion or damage, and making any necessary repairs.

- Steel Structure Warehouse

- Steel Structure Workshop

- Poultry Steel Structure

- Multi-storey Steel Structure

- School Steel Building

- Hospital Steel Structure

- Hotel Steel Building

- Stadium Steel Structure

- Airport Steel Structure

- Train Station Steel Structure

- Light Steel Villa

- Membrane Structure

- Steel Structure Buildings