- Steel Structure Warehouse

- Steel Structure Workshop

- Poultry Steel Structure

- Multi-storey Steel Structure

- School Steel Building

- Hospital Steel Structure

- Hotel Steel Building

- Stadium Steel Structure

- Airport Steel Structure

- Train Station Steel Structure

- Light Steel Villa

- Membrane Structure

- Steel Structure Buildings

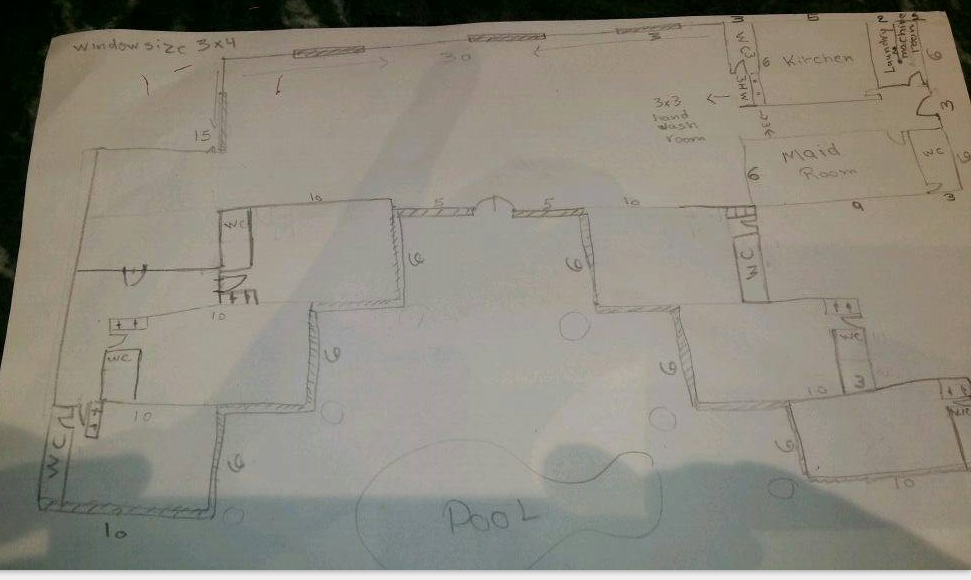

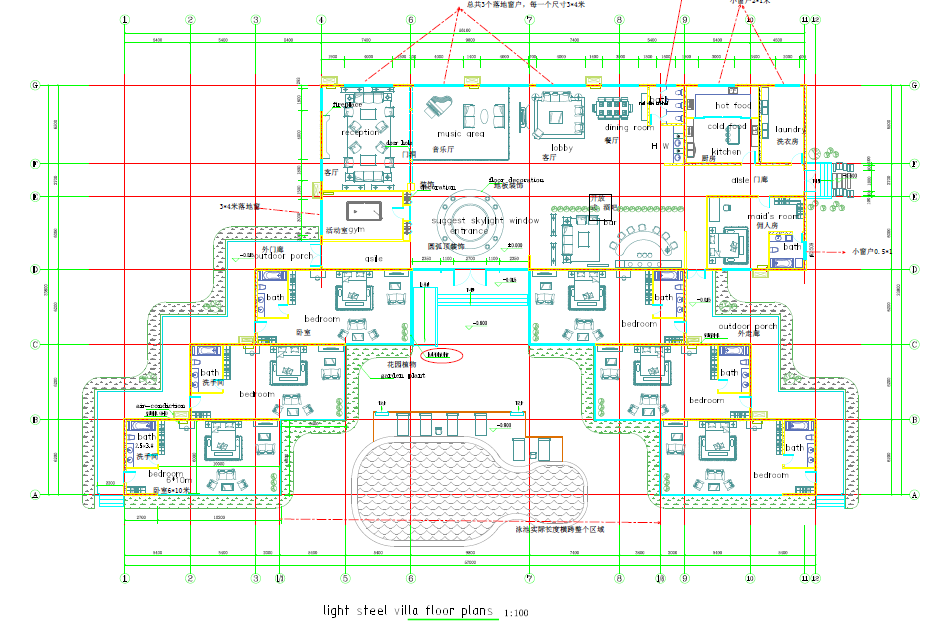

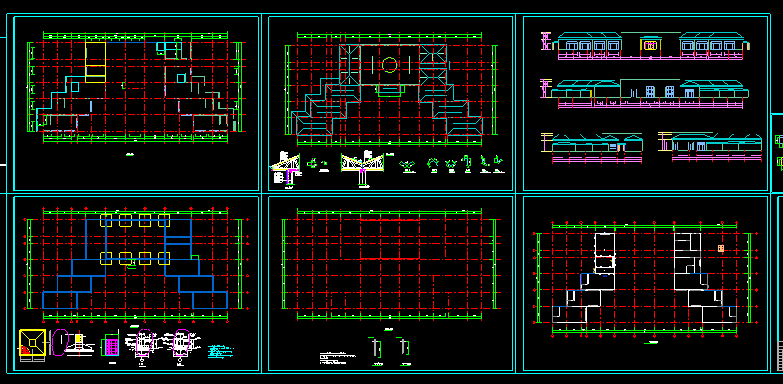

Prefabricated Modern Luxury Light Steel Villa House In UAE

| Categories | Light Steel Villa |

|---|---|

| Brand | ZYM steel structure building Manufacturer |

| Update Time | Apr 27,2025 |

Generally the size of light steel frame villa is more than 500sqm, always double-floors or three-layers steel frame type. But if one prefabricated house size is more than 1000sqm,it will be looks like a palace.

This passage will answer you the following questions:

What is the light gauge steel prefabricated villa?

Why build the light steel frame prefabricated house?

How to build a luxury light steel frame villa for your self?

Let me introduce how we make this palace from a drawing comes to truth.

Project Process

Light gauge steel prefabricated

Villa insulation system

1. Out panel :Metallic decoration board/ Stone painting/ Cement fiber

2. Cold region plus XPS board(1200mmX600)

3. Moisture proof paper(1.5mx0.5mm)

4. Square tube(heat insulation: filling the 150mm glass wool 12kg)

5. OSB panel(Specification 1220x2440x9/10/12/15/18mm)

Inner wall:

1. Gypsum board(Specification 1200X3000/2400mm,Thinkness: 9/12mm )

2. Interior wall use putty paint

3,Decoration board,no need Gypsum board(Client choose inner decoration board)

Floor

1. The floor beams covered with prefabricated floor plate

2. Above the floor steel plate covered with a fine steel first

3. Second doused with 80~120mm cement

4. Ground of the top-level selection of ceramic tile or wood floor. Choose ceramic tile for bathroom and kitchen

Ceiling

1. Square tube structure(filling the 150mm glass wool 12kg)

2. Choose Mineral Wool Board or Gypsum Board for the living room and bedroom, PVC Board or Aluminum ceiling for Bathroom and kitchen

Roofing

1. Square tube roof structure

2. 12~15mm OSB panel

3. 3mm SBS modified asphalt waterproofing membrane

4. Asphalt tile / Colored steel roof tile

Not only sell materials ,but also help client to finish her dream,we help to choose all the bathroom and kitchen equipments.

Even the inner decoration panel,the lobby steel structure dome,we all design and purchase for clients.

All ceramics,closestool,basin,shower,tub,we buy for clients with a very good price and quality.

All the model and color and type are choosen by clients.

For further information feel free to contact us.

- Steel Structure Warehouse

- Steel Structure Workshop

- Poultry Steel Structure

- Multi-storey Steel Structure

- School Steel Building

- Hospital Steel Structure

- Hotel Steel Building

- Stadium Steel Structure

- Airport Steel Structure

- Train Station Steel Structure

- Light Steel Villa

- Membrane Structure

- Steel Structure Buildings