Metal Steel Structure Workshop Building With Storage Space And Good Heat Preservation From China

- Steel Structure Warehouse

- Steel Structure Workshop

- Poultry Steel Structure

- Multi-storey Steel Structure

- School Steel Building

- Hospital Steel Structure

- Hotel Steel Building

- Stadium Steel Structure

- Airport Steel Structure

- Train Station Steel Structure

- Light Steel Villa

- Membrane Structure

- Steel Structure Buildings

Metal Steel Structure Workshop Building With Storage Space And Good Heat Preservation From China

| Categories | Steel Structure Workshop |

|---|---|

| Brand | ZYM steel structure building Manufacturer |

| Model | ZYM2 |

| FOB port | Qingdao Guangdong Shanghai |

| Terms of Payment | L/C, D/A, Western Union, T/T |

| Update Time | Apr 27,2025 |

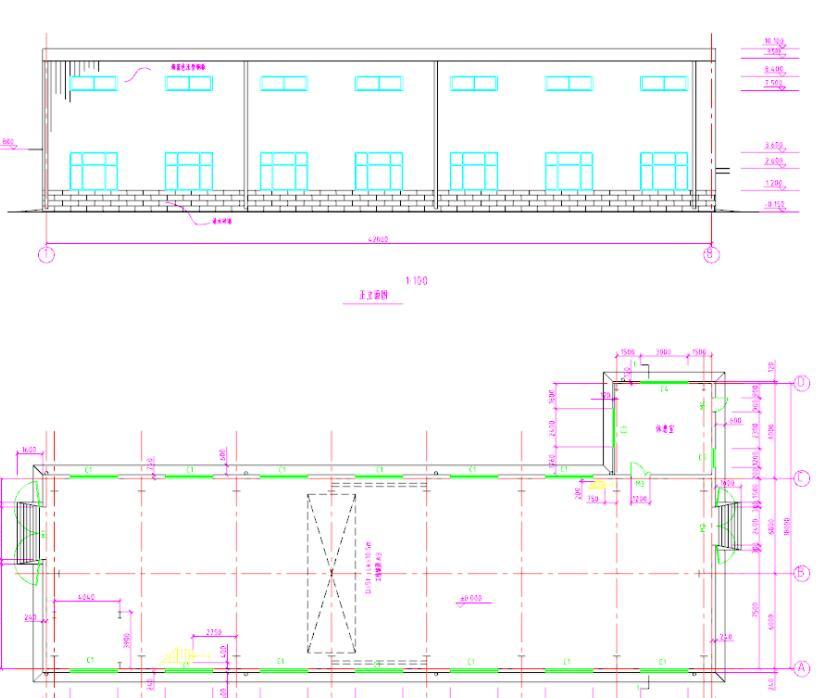

How to build a metal prefab steel structure workshop with storage space

Ⅰ-Communication And Design

According to our client's demand , we design the steel structure workshop . Our before-sale consulting team provide free service . The clients don't have the drawing ,but after the following answers , we provide the drawings .

Wind load (max. Wind speed)

Snow load (max. Snow height)

Anti-earthquake

Brick wall needed or not If yes, 1.2m high or 1.5m high

Thermal insulation If yes, EPS, fiberglass wool, rockwool, PU sandwich panels will be suggested.

Door quantity & size

Window quantity

Crane needed or not

Every details will be confirmed , then we will provide the optimal prefab workshop plans for our clients

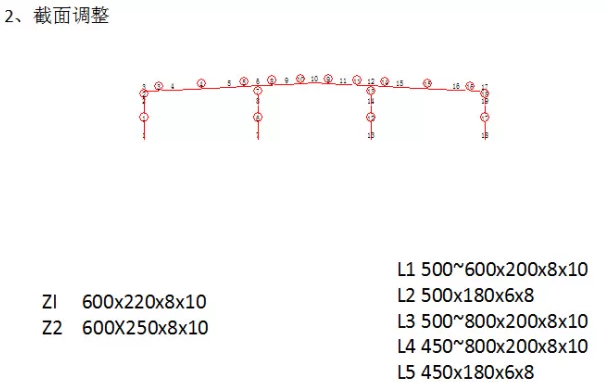

According to all the welding joint types in the construction drawing, Tthe welding engineer will make a comprehensive consideration,such as the material of the base material, the thickness and the welding position, combined with the welding method used .

Ⅲ Erection

- Steel Structure Warehouse

- Steel Structure Workshop

- Poultry Steel Structure

- Multi-storey Steel Structure

- School Steel Building

- Hospital Steel Structure

- Hotel Steel Building

- Stadium Steel Structure

- Airport Steel Structure

- Train Station Steel Structure

- Light Steel Villa

- Membrane Structure

- Steel Structure Buildings