europe steel structure on-site installation

Overview of on-site installation plan

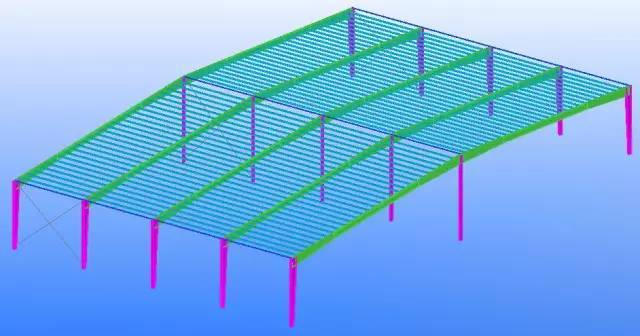

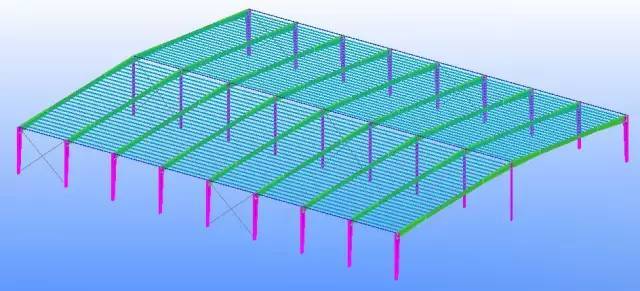

The structural form of this steel structural engineering is frame. Combined with the component form, weight, location and actual situation of the construction site, as well as the various lifting parameters and performances of the tower crane set on site, the steel structure of this project is installed in a comprehensive way.

1. Method of on-site installation of steel structures:

The frame columns, beams, and other components of the factory building are relatively light in weight, and the NK250 25t truck crane is mainly used for lifting and positioning.

2. Installation sequence of steel structures on site:

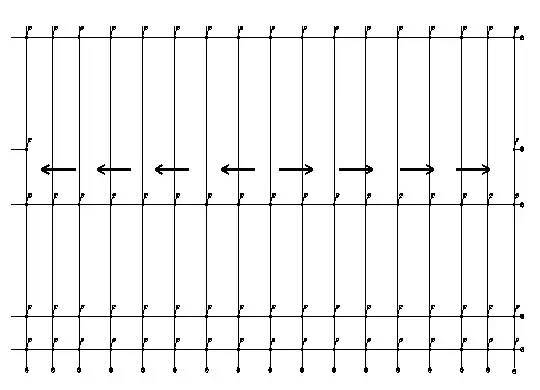

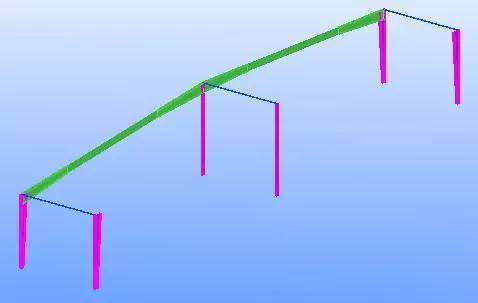

The steel structure hoisting adopts the principle of "starting from the middle and then the outer side, starting from the columns and then the beams, and starting from the bottom and then the top". A stable frame system is first formed in the middle of the factory building, and then the remaining steel columns and beams are symmetrically installed by pushing towards both ends. The sequence is shown in the following figure:

Analysis of Main Installation Components

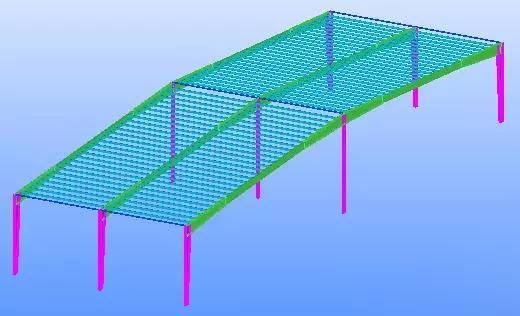

The main components of the project are steel columns, steel beams, purlins, slant support and other components. The steel material is Q355B. The weight is not too heavy,

Selection and arrangement of lifting equipment

For the selection of cranes, according to the site layout plan, a total of 5 steel structure plants and steel structural engineering need to be installed. In combination with its lifting performance and working condition analysis, 4 NK250 25t truck cranes are configured on site.

Steel structure installation process

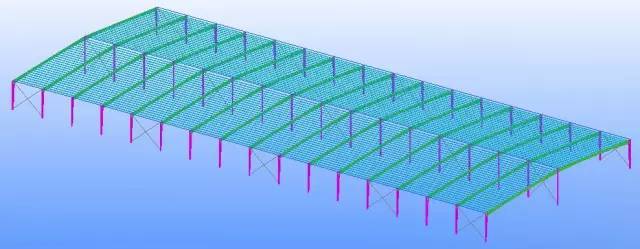

1. Overall installation process (taking a freezer as an example)

Retesting of anchor bolts → unloading of steel components → entry inspection of components → direct lifting in place by truck crane → temporary fastening of anchor bolts → temporary fastening of cable and wind ropes → adjustment of steel column axis position and verticality → fastening and welding of steel column bolts and column foot pressure plates → installation of next steel column → installation of tie rods between steel columns → formation of the first stable grid system → assembly of steel roof truss ground into a whole and double machine lifting in place, Forming the first steel roof truss → symmetrically installing columns and roof truss systems on both sides →... → and so on → installation completed, structural acceptance.

2. Division of steel structure installation area

This project consists of five parts: meat freezing, meat market, vegetable storage, vegetable market, and open sales area. According to the division of construction flow sections, it is divided into five areas, as shown in the following figure.

3. Overall installation sequence of steel structure

According to the overall deployment of the project, it is planned to arrange two construction teams to carry out construction simultaneously. The overall construction sequence of the five areas is: Zone 1, Zone 2... Zone 5.

For the same factory building, the installation sequence of steel components adopts the method of "reducing errors, from the middle to both ends" for installation.

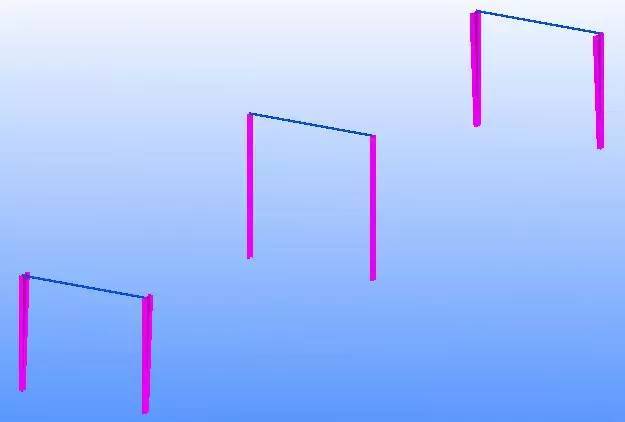

4. Installation sequence of steel structures (taking a freezer as an example)

(1) Install the first row of steel columns.

(2) Install the second row of steel columns.

(3) Install connecting beams (or tie bars) between steel columns.

(4) Install the first steel roof truss using dual crane lifting.

(5) Install the second steel roof truss using dual crane lifting.

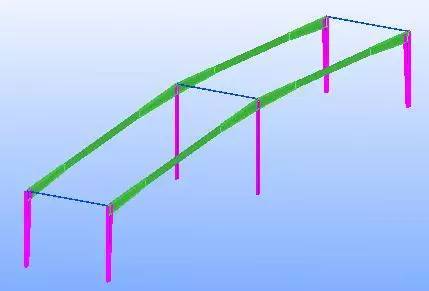

(6) Install purlins between two roof trusses to form a stable framework system.

(7) Continue to install the steel columns, connecting beams, roof trusses, and purlins of the next rigid frame.

(8) Continue to install the roof truss in the above order, and the support between the columns is also interspersed for installation.

(9) Continue with installation.

(10) The installation of the roof truss has been completed.

#building steel frame structure

Read More

For further information feel free to contact us

Email:sales@zyminfra.com

Tel/Whatapp:0086-18561962040