The Basic Knowledge of Steel Structures(Part 2)

Main Steel Structure Technical Content

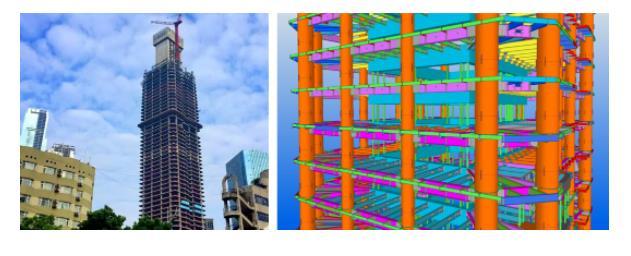

1.High rise steel structure technology

According to the building height and design requirements, frames, frame supports, tubes, and mega frame structures can be used, and their components can be made of steel, reinforced concrete, or steel tube concrete. Steel components are lightweight and have good ductility, and can be made of welded or rolled sections, suitable for ultra high rise buildings; Stiffened reinforced concrete components have high stiffness and good fire resistance, making them suitable for mid to high-rise buildings or bottom structures; Steel tube concrete construction is simple and only used for column structures.

2.Space Steel Structure Technology

The spatial steel structure has light weight, high stiffness, beautiful appearance, and fast construction speed. The spherical node flat grid, multi-layer variable cross-section grid, and grid shell with steel pipes as members are the most commonly used structural types of spatial steel structures in China. It has the advantages of high spatial stiffness and low steel consumption, and can provide comprehensive CAD in design, construction, and inspection procedures. In addition to grid structures, spatial structures also include large-span suspension structures, cable membrane structures, etc.

3.Light steel structure technology

Accompanied by a new structural form consisting of walls and roof enclosure made of lightweight colored steel plates. A lightweight steel structural system consisting of large cross-section thin-walled H-shaped steel wall beams and roof purlins welded or rolled with steel plates of 5mm or more, flexible support systems made of round steel, and high-strength bolt connections. The column spacing can range from 6m to 9m, the span can reach 30m or more, the height can reach more than ten meters, and the steel consumption is 20-30kg/m2. There are now standardized design procedures and specialized production enterprises, with good product quality, fast installation speed, light weight, low investment, and construction not limited by seasons, suitable for various light industrial factories.

4.Steel Concrete Composite Structure Technology

The load-bearing structure of beams and columns composed of shaped steel or steel management and concrete components is a steel-concrete composite structure, and its application scope has been expanding in recent years. The composite structure has the advantages of both steel and concrete, with high overall strength, good rigidity, and good seismic performance. When using an outer concrete structure, it has better fire resistance and corrosion resistance. Composite structural components can generally reduce the amount of steel used by 15-20%. Composite floors and steel tube concrete components also have the advantages of less or no formwork support, convenient and fast construction, and have great potential for promotion. Suitable for frame beams, columns, and floors of multi-story or high-rise buildings with large loads, as well as industrial building columns and floors.

5.High strength bolt connection and welding technology

High strength bolts transmit stress through friction and are composed of three parts: bolts, nuts, and washers. The high-strength bolt connection has the advantages of simple construction, flexible removal, high bearing capacity, good fatigue resistance and self-locking performance, and high safety. It has replaced riveting and partial welding in engineering and has become the main connection method in steel structure production and installation. The steel components produced in the workshop should use automatic multi wire arc submerged welding for thick plates, and fusion nozzle electroslag welding and other technologies should be used for box column partitions. During on-site installation and construction, semi-automatic welding technology, gas shielded flux cored welding wire, and self-protection flux cored welding wire technology should be used.

6.Steel Structure Protection Technology

Steel structure protection includes fire prevention, corrosion prevention, and rust prevention. Generally, it is not necessary to undergo rust prevention treatment after being treated with fireproof coatings, but in buildings with corrosive gases, anti-corrosion treatment is still required. There are many types of fireproof coatings in China, such as TN series, MC-10, etc. Among them, MC-10 fireproof coatings include alkyd enamel, chlorinated rubber paint, fluororubber paint, and chlorosulfonated paint. During construction, appropriate coatings and coating thicknesses should be selected based on the steel structure type, fire resistance rating requirements, and environmental requirements.

#prefabricated steel structure

#light steel structure prefab house home

#industrial building metal steel structure

Read More

For further information feel free to contact us

Email:sales@zyminfra.com

Tel/Whatapp:0086-18561962040